Ba

1−xLa

x共Fe

1/2Nb

1/2兲

1−x/4O

3共0艋x艋0.2兲 has a monoclinic structure solid solutions up to x艋0.2, the lattice parameters decrease with an increasing La concentration. The temperature dependence of the dielectric constant of the La-doped Ba 共FeNb兲

1/2O

3was measured with different La contents, showing that the dielectric permittivity is higher than 10

5at an 8 mol% La concentration. The present dielectric dispersion was interpreted on the basis of the interfacial polarization at the grain-boundary region. © 2004 American Institute of Physics. [DOI: 10.1063/1.1804243]

I. INTRODUCTION

Oxides with perovskite structures and high dielectric constants play an important role in microelectronics, and have numerous technological applications. They have been used as memory devices and capacitors. Dielectric materials always exhibit with ferroelectric or relaxor properties. How- ever, both kinds of materials have dielectric constants that vary hugely with temperature, a property which is unfavor- able for many applications. However, most perovskite struc- ture dielectric materials contain lead, but the environment is polluted by lead. Therefore, lead-free materials with high dielectric constants are becoming increasingly attractive.

A lead-free perovskite-like oxide, CaCu

3Ti

4O

121,2was recently reported to have an extraordinarily high static di- electric constant of

0⬇10

5at room temperature. Further- more, while Li and Ti-doped NiO is a new oxide with a high dielectric constant,

3it does not have a perovskite structure and it is not non ferroelectric, but it does have a low- frequency dielectric constant of

0⬇10

4– 10

5at room tem- perature. Ba 共FeNb兲

1/2O

3is a relaxor type of ferroelectric ma- terial that has a partially disordered perovskite structure.

4,5Its curve of dielectric permittivity versus temperature in- cludes a plateau after the maximum. These relaxor ferroelec- tric properties follow from the broad dielectric transitions, known as the diffused phase transitions with a strong fre- quency dispersion.

6,7This investigation examines the effects of La doping on the Ba 共FeNb兲

1/2O

3samples prepared according to the for- mula Ba

1−xLa

x共Fe

0.5Nb

0.5兲

1−x/4O

3共0⬍x⬍0.2兲. The charges of the La ion were compensated by the appearance of the B-site vacancies. Incorporating La

2O

3into the A-site sublat-

tice of the perovskite structure stabilizes in the monoclinic phase, and the polycrystalline materials of such modified di- electrics were prepared by a solid-state reaction method. The microstructures and the corresponding dielectric properties were characterized.

II. EXPERIMENT

The compounds used in this investigation were prepared by a routine solid-state reaction route and starting materials, which included BaCO

3(99.9% pure, NOAH technologies corporation, San Antonio ), Fe

2O

3(99.9% pure, Alfa Asear Co.), Nb

2O

5(99.9% pure, Aldrich Chemical Co.), and La

2O

3(99.99% pure, Showa Chemical Co., Ltd.). The donor 共La兲 doping concentration were varied from 0.02 to 0.2 mol% and the raw powders were based on the formula Ba

1−xLa

x共Fe

0.5Nb

0.5兲

1−x/4O

3. The columbite precursor method was used for the FeNbO

4powders, first synthesized by prereacting the Fe

2O

3and Nb

2O

5ball milled with acetone in a polypropylene jar for 24 h. The mixture was then dried at 100° C and calcined at 1100° C for 4 h in air. Secondly, the Ba

1−xLa

x共Fe

0.5Nb

0.5兲

1−x/4O

3powders were prepared by the FeNbO

4, BaCO

3, and La

2O

3ball milled with acetone in a polypropylene jar for 24 h again, and after drying, they were calcined at 950° C for 5 h in air. 1 wt% of polyvinyl alcohol was usually added to the synthesized powders as the sinter- ing aid. The calcined powders were regrounded and pressed at 200 MPa in the form of disks of 10– 11 mm in diameter and thicknesses of 2 – 4 mm. Finally, the pellets placed on an aluminum oxide crucible were sintered in air at 1200– 1350° C for 4 h at a ramping rate of 5 ° C / min. The electrodes for measurements were deposited on grinded disk surfaces by rubbing on the In– Ga alloy.

The phase purity, the structure, and the lattice parameters of the sample were determined by x-ray power diffraction

a)Author to whom correspondence should be addressed; electronic mail:

enphei@mail.ncku.edu.tw

0021-8979/2004/96(11)/6624/5/$22.00 6624 © 2004 American Institute of Physics

with CuK ␣ radiation at room temperature. The particle mor- phology and the grain size were characterized by scanning electron microscopy (SEM). The density of sintered Ba

1−xLa

x共Fe

0.5Nb

0.5兲

1−x/4O

3was measured using the Archimedes method in de-ionized water. The dielectric con- stant and dielectric loss were measured from 100 Hz to 100 kHz at room temperature using an LCR (HP4284A) meter.

III. RESULT AND DISCUSSION

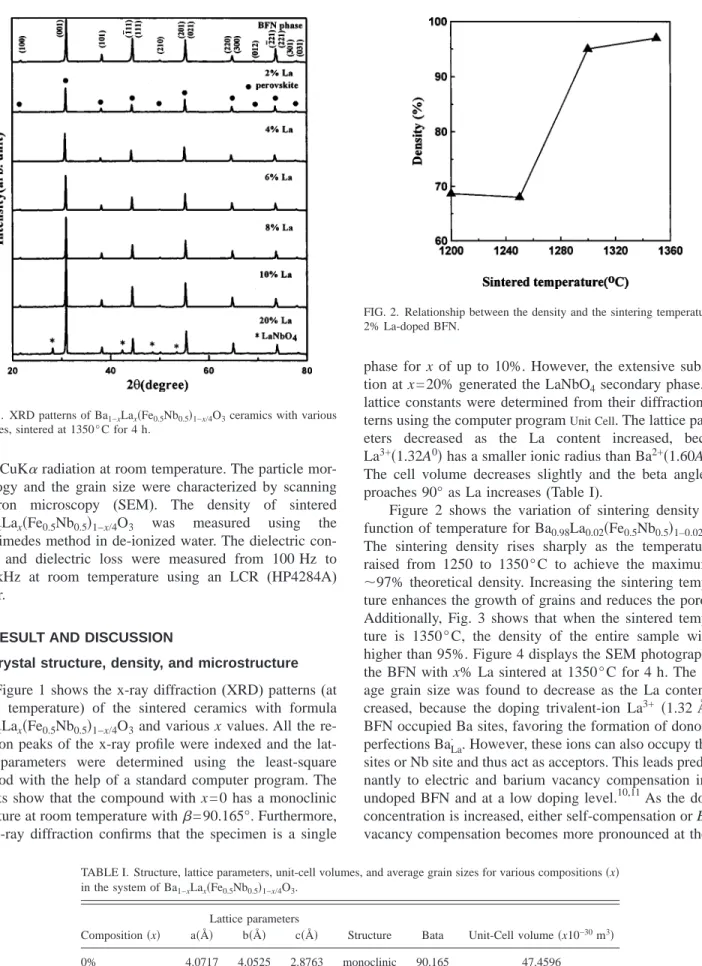

A. Crystal structure, density, and microstructure Figure 1 shows the x-ray diffraction (XRD) patterns (at room temperature) of the sintered ceramics with formula Ba

1−xLa

x共Fe

0.5Nb

0.5兲

1−x/4O

3and various x values. All the re- flection peaks of the x-ray profile were indexed and the lat- tice parameters were determined using the least-square method with the help of a standard computer program. The results show that the compound with x = 0 has a monoclinic structure at room temperature with  = 90.165°. Furthermore, the x-ray diffraction confirms that the specimen is a single

phase for x of up to 10%. However, the extensive substitu- tion at x = 20% generated the LaNbO

4secondary phase. The lattice constants were determined from their diffraction pat- terns using the computer program

Unit Cell. The lattice param- eters decreased as the La content increased, because La

3+共1.32A

0兲 has a smaller ionic radius than Ba

2+共1.60A

0兲.

8,9The cell volume decreases slightly and the beta angle ap- proaches 90° as La increases (Table I).

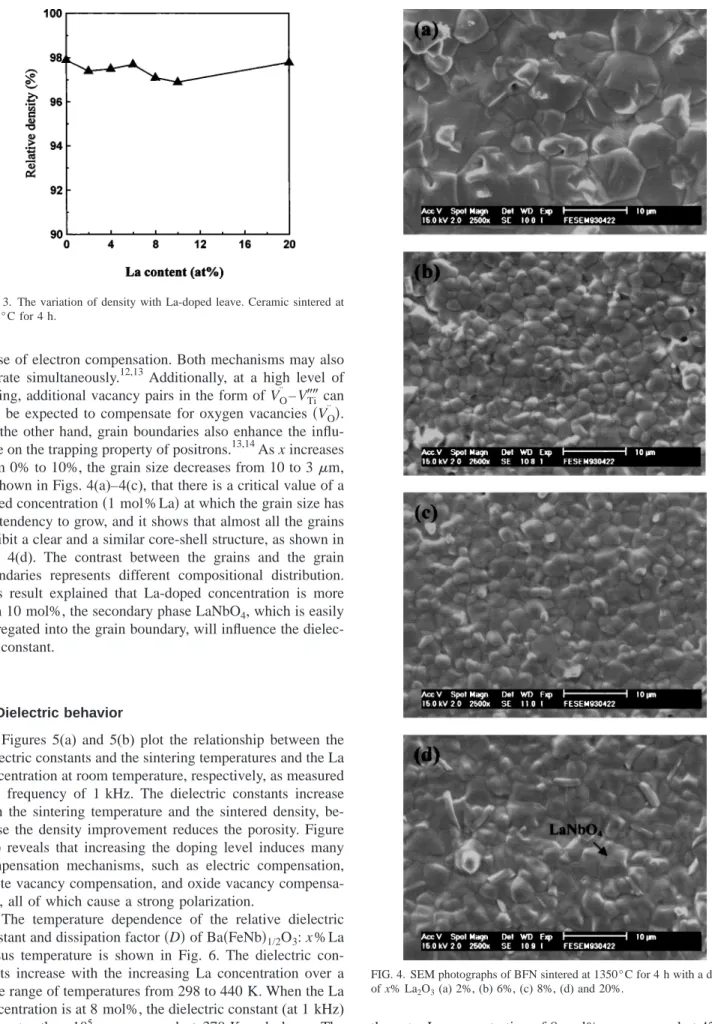

Figure 2 shows the variation of sintering density as a function of temperature for Ba

0.98La

0.02共Fe

0.5Nb

0.5兲

1–0.02/4O

3. The sintering density rises sharply as the temperature is raised from 1250 to 1350° C to achieve the maximum of

⬃97% theoretical density. Increasing the sintering tempera- ture enhances the growth of grains and reduces the porosity.

Additionally, Fig. 3 shows that when the sintered tempera- ture is 1350° C, the density of the entire sample will be higher than 95%. Figure 4 displays the SEM photographs of the BFN with x% La sintered at 1350° C for 4 h. The aver- age grain size was found to decrease as the La content in- creased, because the doping trivalent-ion La

3+共1.32 Å兲 in BFN occupied Ba sites, favoring the formation of donor im- perfections Ba

La·. However, these ions can also occupy the Fe sites or Nb site and thus act as acceptors. This leads predomi- nantly to electric and barium vacancy compensation in the undoped BFN and at a low doping level.

10,11As the doping concentration is increased, either self-compensation or B-site vacancy compensation becomes more pronounced at the ex-

FIG. 1. XRD patterns of Ba1−xLax共Fe0.5Nb0.5兲1−x/4O3ceramics with various x values, sintered at 1350° C for 4 h.

TABLE I. Structure, lattice parameters, unit-cell volumes, and average grain sizes for various compositions共x兲 in the system of Ba1−xLax共Fe0.5Nb0.5兲1−x/4O3.

Lattice parameters

Composition共x兲 a共Å兲 b共Å兲 c共Å兲 Structure Bata Unit-Cell volume共x10−30m3兲

0% 4.0717 4.0525 2.8763 monoclinic 90.165 47.4596

2% 4.0736 4.0485 2.8789 monoclinic 90.255 47.4773

4% 4.0629 4.0498 2.8709 monoclinic 90.108 47.2384

6% 4.0640 4.0540 2.8748 monoclinic 90.097 47.3637

8% 4.0574 4.0452 2.8677 monoclinic 90.053 47.0665

10% 4.0537 4.0472 2.8655 monoclinic 90.034 46.9841

20% 4.0455 4.0380 2.8600 monoclinic 90.024 46.7208

FIG. 2. Relationship between the density and the sintering temperature for 2% La-doped BFN.

pense of electron compensation. Both mechanisms may also operate simultaneously.

12,13Additionally, at a high level of doping, additional vacancy pairs in the form of V

O¨– V

Ti⬙⬙ can also be expected to compensate for oxygen vacancies 共V

O¨

兲.

On the other hand, grain boundaries also enhance the influ- ence on the trapping property of positrons.

13,14As x increases from 0% to 10%, the grain size decreases from 10 to 3 m, as shown in Figs. 4 (a)–4(c), that there is a critical value of a doped concentration 共1 mol%La兲 at which the grain size has the tendency to grow, and it shows that almost all the grains exhibit a clear and a similar core-shell structure, as shown in Fig. 4 (d). The contrast between the grains and the grain boundaries represents different compositional distribution.

This result explained that La-doped concentration is more than 10 mol%, the secondary phase LaNbO

4, which is easily segregated into the grain boundary, will influence the dielec- tric constant.

B. Dielectric behavior

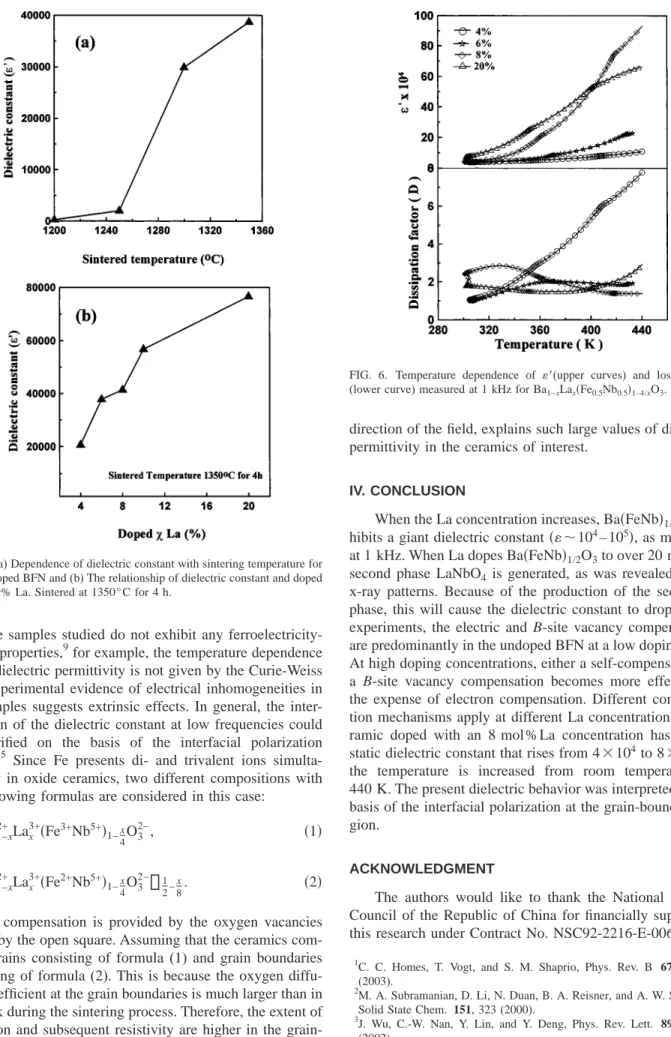

Figures 5 (a) and 5(b) plot the relationship between the dielectric constants and the sintering temperatures and the La concentration at room temperature, respectively, as measured at a frequency of 1 kHz. The dielectric constants increase with the sintering temperature and the sintered density, be- cause the density improvement reduces the porosity. Figure 5 (b) reveals that increasing the doping level induces many compensation mechanisms, such as electric compensation, B-site vacancy compensation, and oxide vacancy compensa- tion, all of which cause a strong polarization.

The temperature dependence of the relative dielectric constant and dissipation factor 共D兲 of Ba共FeNb兲

1/2O

3: x % La versus temperature is shown in Fig. 6. The dielectric con- stants increase with the increasing La concentration over a wide range of temperatures from 298 to 440 K. When the La concentration is at 8 mol%, the dielectric constant (at 1 kHz) is greater than 10

5, as measured at 370 K and above. The dissipation factor 共D兲 depends weakly on temperature. The dielectric constant at a La concentration of 20 mol% is lower

than at a La concentration of 8 mol%, as measured at 420 K and above. This effect is related to the presence of the second phase.

FIG. 3. The variation of density with La-doped leave. Ceramic sintered at 1350° C for 4 h.

FIG. 4. SEM photographs of BFN sintered at 1350° C for 4 h with a dopant of x% La2O3(a) 2%, (b) 6%, (c) 8%, (d) and 20%.

The samples studied do not exhibit any ferroelectricity- related properties,

9for example, the temperature dependence of the dielectric permittivity is not given by the Curie-Weiss law. Experimental evidence of electrical inhomogeneities in the samples suggests extrinsic effects. In general, the inter- pretation of the dielectric constant at low frequencies could be clarified on the basis of the interfacial polarization model.

15Since Fe presents di- and trivalent ions simulta- neously in oxide ceramics, two different compositions with the following formulas are considered in this case:

Ba

1−x2+La

x3+共Fe

3+Nb

5+兲

1−x4

O

32−, 共1兲

Ba

1−x2+La

x3+共Fe

2+Nb

5+兲

1−x 4O

32−짳

12−x

8

. 共2兲

Charge compensation is provided by the oxygen vacancies shown by the open square. Assuming that the ceramics com- prise grains consisting of formula (1) and grain boundaries consisting of formula (2). This is because the oxygen diffu- sion coefficient at the grain boundaries is much larger than in the bulk during the sintering process. Therefore, the extent of oxidation and subsequent resistivity are higher in the grain- boundary layers than in the grain. This fact, taken with the relatively small total width of the grain boundaries in the

direction of the field, explains such large values of dielectric permittivity in the ceramics of interest.

IV. CONCLUSION

When the La concentration increases, Ba 共FeNb兲

1/2O

3ex- hibits a giant dielectric constant 共⬃10

4– 10

5兲, as measured at 1 kHz. When La dopes Ba 共FeNb兲

1/2O

3to over 20 mol%, a second phase LaNbO

4is generated, as was revealed by the x-ray patterns. Because of the production of the secondary phase, this will cause the dielectric constant to drop. In the experiments, the electric and B-site vacancy compensations are predominantly in the undoped BFN at a low doping level.

At high doping concentrations, either a self-compensation or a B-site vacancy compensation becomes more effective at the expense of electron compensation. Different compensa- tion mechanisms apply at different La concentrations. A ce- ramic doped with an 8 mol% La concentration has a high static dielectric constant that rises from 4 ⫻10

4to 8 ⫻10

5as the temperature is increased from room temperature to 440 K. The present dielectric behavior was interpreted on the basis of the interfacial polarization at the grain-boundary re- gion.

ACKNOWLEDGMENT

The authors would like to thank the National Science Council of the Republic of China for financially supporting this research under Contract No. NSC92-2216-E-006-026.

1C. C. Homes, T. Vogt, and S. M. Shaprio, Phys. Rev. B 67, 092106 (2003).

2M. A. Subramanian, D. Li, N. Duan, B. A. Reisner, and A. W. Sleight, J.

Solid State Chem. 151, 323(2000).

3J. Wu, C.-W. Nan, Y. Lin, and Y. Deng, Phys. Rev. Lett. 89, 217601 (2002).

4S. Saha and T. P. Sinha, J. Phys.: Condens. Matter 14, 249(2002).

5W. Z. Zhu, A. Kholkin, P. Q. Mantas, and J. L. Baptista, J. Mater. Sci. 36, FIG. 6. Temperature dependence of ⬘(upper curves) and loss tangent (lower curve) measured at 1 kHz for Ba1−xLax共Fe0.5Nb0.5兲1–4/xO3.

FIG. 5.(a) Dependence of dielectric constant with sintering temperature for 4% La-doped BFN and(b) The relationship of dielectric constant and doped level of x% La. Sintered at 1350° C for 4 h.