Interface Engineering to Enhance the E

fficiency of Conventional

Polymer Solar Cells by Alcohol-/Water-Soluble C

60

Materials Doped

with Alkali Carbonates

Yu-Ying Lai, Ping-I Shih, Yi-Peng Li, Che-En Tsai, Jhong-Sian Wu, Yen-Ju Cheng,* and Chain-Shu Hsu*

Department of Applied Chemistry, National Chiao Tung University, 1001 Ta Hsueh Road Hsin-Chu, 30010, Taiwan

*

S Supporting InformationABSTRACT:

Two new C

60-based n-type materials, EGMC

−

OH

and EGMC

−COOH, functionalized with hydrophilic

triethylene glycol groups (TEGs), have been synthesized and

employed in conventional polymer solar cells. With the

assistance of the TEG-based surfactant, EGMC

−OH and

EGMC

−COOH can be dissolved in highly polar solvents to

implement the polar/nonpolar orthogonal solvent strategy,

forming an electron modi

fication layer (EML) without eroding the underlying active layer. Multilayer conventional solar cells on

the basis of ITO/PEDOT:PSS/P3HT:PC

61BM/EML/Ca/Al con

figuration with the insertion of the EGMC−OH and EGMC−

COOH

EML between the active layer and the electrode have thus been successfully realized by cost-e

ffective solution processing

techniques. Moreover, the electron conductivity of the EML can be improved by incorporating alkali carbonates into the

EGMC

−COOH EML. Compared to the pristine device with a PCE of 3.61%, the devices modified by the Li

2CO

3-doped

EGMC

−COOH EML achieved a highest PCE of 4.29%. Furthermore, we demonstrated that the formation of the EGMC−

COOH

EML can be utilized as a general approach in the fabrication of highly e

fficient multilayer conventional devices. With the

incorporation of the EGMC

−COOH doped with 40 wt % Li

2CO

3, the PCDCTBT

−C8:PC

71BM-based device exhibited a

superior PCE of 4.51%, which outperformed the corresponding nonmodi

fied device with a PCE of 3.63%.

KEYWORDS:

polymer solar cells, interface engineering, hydrophilic fullerene materials, electron-selective layer, dopant,

alkali carbonates

■

INTRODUCTION

Bulk heterojunction (BHJ) solar cells based on polymer/

fullerene blends have attracted enormous attention in the past

decades due to their potential for fabrication onto large areas of

lightweight and

flexible substrates by low-cost solution

processing.

1A conventional BHJ polymer solar cell (PSC)

with an active layer sandwiched by a low-work-function

aluminum cathode and a hole-conducting

poly(3,4-ethylenedioxylenethiophene):poly(styrenesulfonic acid)

(PE-DOT:PSS) layer on top of an indium tin oxide (ITO)

substrate is the most widely used and researched device

con

figuration.

2By reversing the polarity of charge collection in

the conventional cell, stable Ag can substitute for

air-sensitive Al as the anodic electrode to construct a PSC with an

inverted con

figuration.

3In addition to development of p-type/

n-type photoactive materials and control of nanomorphology,

4interface engineering of multilayer conventional and inverted

solar cells plays a critical role in achieving high e

fficiency and

stability.

5One of the directions of interfacial engineering is

focused on the incorporation of an electron-selective layer, such

as ZnO,

6TiO

x,

7LiF,

8Cs

2CO

3,

9poly(ethylene oxide),

10and

conjugated polyelectrolytes

11between the active layer and the

metal cathode for modulating the energy level alignment at the

electrode/active layer interface, inducing electron-extracting/

hole-blocking abilities, and facilitating electron transportation.

Fullerene-based materials, in particular, emerge as the most

superior n-type components to construct an electron-selective

modi

fication layer (EML) because their physical and electrical

properties can be tailored and manipulated by attaching various

addends on the core of fullerene.

12For example, the

fluorinated

fullerene with the lower surface energy tends to self-assemble

on the surface of the active layer during spin-coating to enhance

the device performance.

12a,bMore importantly, the functional

groups incorporated into C

60molecules can be speci

fically

designed for ful

filling the processing requirements. For PSCs,

multilayer structures are fabricated by layer-by-layer

cost-effective spin-coating. One of the encountered challenges for

solution processing techniques is the erosion of the bottom

layer caused by organic solvents used in the subsequent

step.

12g,h,13For inverted PSCs, a solution of active layer needs

to be deposited on top of a fullerene-based EML. Therefore,

the development of chemically self-assembled

12c,dand/or

cross-linked fullerene materials

12e−hto generate a robust and

solvent-resistant EML has overcome the processing difficulties and thus

successfully improved the device characteristics. With opposite

sequence in a conventional device, however, a fullerene-based

Received: March 18, 2013 Accepted: May 20, 2013 Published: May 20, 2013

EML should be formed by spin-coating on top of the active

layer. Considering that hydrophobic active layers such as

P3HT/PC

61BM are soluble in nonpolar organic solvents but

almost insoluble in highly polar solvents, utilization of

orthogonal solvents (i.e., nonpolar/polar) to construct multiple

organic layers is a straightforward and practical strategy.

14In

this research, we have designed and synthesized two fullerene

materials, EGMC

−OH and EGMC−COOH (Scheme 1),

containing hydrophilic triethylene glycol side chains. The two

hydroxyl groups in EGMC−OH are further end-capped by two

phthalic acids to yield EGMC

−COOH. With the aid of

triethylene glycol group (TEG)-based neutral surfactants, these

C

60materials with enhanced hydrophilic nature can be

dissolved in the polar 2-ethoxyethanol/H

2O solvent which

was spin-cast to form an EML without destroying the

underneath active layer. Therefore, we can successfully

intercalate an EML between the active layer and the Ca/Al

electrode in a conventional device. It has been demonstrated

that the electron-transporting properties of organic

semi-conductors can be dramatically enhanced by adding alkali

carbonates as n-dopants.

15Alkali carbonates are ionic and

highly polar compounds that can only be soluble in water. An

organic active layer, such as P3HT/PC

61BM, is not compatible

with the ionic or highly polar compounds. Therefore, the

attempt of spin-coating pure alkali carbonates in aqueous

solution on top of the organic active layer is not successful.

Thermal vacuum coevaporation is the typical way to generate a

thin

film containing an alkali carbonate guest in a host

material.

15a,b,d,g,hEncouragingly, by the combination of water-/

alcohol-soluble EGMC

−OH and EGMC−COOH as the host

materials with water-soluble alkali carbonates as the dopants, an

n-doped C

60-based EML can be easily generated by

cost-e

ffective spin-coating processing. The P3HT:PC

61BM-based

and

poly(carbazole-dicyclopentathiophene-alt-benzothiadia-zole) (PCDCTBT

−C8, Scheme 1):PC

71BM-based devices

integrating alkali carbonate-doped EGMC

−COOH as the

EMLs exhibited 19% and 24% improvement in e

fficiency,

respectively, compared to their corresponding nonmodi

fied

cells.

■

EXPERIMENTAL SECTION

All chemicals were obtained from commercial sources and used as received unless otherwise specified. Anhydrous tetrahydrofuran, toluene, and dichloromethane were obtained from an SD-300 solvent purification system by AsiaWong Enterprise. NMR measurements are reported for Varian Unity-300 and UI-500 spectrometers (1H, 300

MHz;13C, 75 MHz). Chemical shifts (δ values) are reported in parts

per million with respect to Me4Si (δ = 0 ppm) for13C and1H NMR.

Coupling constants (J) are given in Hertz. 13C NMR was proton

broad-band-decoupled. Multiplicities of peaks are denoted by the following abbreviations: s, singlet; d, doublet; t, triplet; m, multiplet; br, broad. Thermogravimetric analysis (TGA) was recorded on a PerkinElmer Pyris analyzer under nitrogen atmosphere at a heating rate of 10°C min−1. Absorption spectra were collected on a HP8453 UV−vis spectrophotometer. Electrochemical cyclic voltammetry (CV) was conducted on a CH Instrument model 611D analyzer. Pt coated with a thin fullerenefilm was used as the working electrode, Ag/Ag+

electrode as the reference electrode, and Pt as the counter electrode, while 0.1 M tetrabutylammonium hexafluorophosphate in o-dichlor-obenzene was the electrolyte. CV curves were calibrated using ferrocence as the standard, whose oxidation potential is set at−4.8 eV with respect to zero vacuum level. The HOMO energy levels were obtained from the equation HOMO = −(Eoxonset − E(ferrocene)onset +

4.8) eV. The LUMO levels were obtained from the equation LUMO = −(Eredonset− E(ferrocene)onset+ 4.8) eV

Synthesis of Tri(ethylene glycol) tert-Butyldimethylsilyl Ether (1). To an anhydrous CH2Cl2(100 mL) solution of triethylene

glycol (49.56 g, 0.33 mol), 4-dimethylaminopyridine (1.613 g, 13 mmol), and triethylamine (6.68 g, 66 mmol) was added dropwise an anhydrous CH2Cl2(25 mL) solution of tert-butyldimethylsilyl chloride

(10 g, 66 mmol) via an addition funnel under nitrogen atmosphere. The mixture was stirred at room temperature for 3 h and extracted with CH2Cl2/NH4Cl(aq)three times. The collected organic layer was

dried over MgSO4,filtered, and evaporated in vacuo. The resultant

residue was then submitted to column chromatography on silica gel (ethyl acetate:hexane = 1:3, v/v) to give a transparent liquid (13.45 g, 77%):1H NMR (CDCl

3, 300 MHz)δ 0.04 (s, 6H, Si(CH3)2), 0.86 (s,

9H, C(CH3)3), 2.60 (br, 1H, OH), 3.53−3.77 (m, 12H, OCH2);13C

NMR (CDCl3, 75 MHz) δ −5.3 (2C, SiCH3), 18.4 (1C, (Si−

C(Me)3), 25.9 (3C, (Si−C(CH3)3), 61.8 (1C, OCH2), 62.7 (1C,

OCH2), 70.4 (1C, OCH2), 70.7 (1C, OCH2), 72.5 (1C, OCH2), 72.7

(2C, OCH2).

Synthesis of Bis(TBDMS-triethylene glycol)-malonate (2). To an anhydrous CH2Cl2 (50 mL) solution of malonic acid (1 g, 9.60

mmol), 4-dimethylaminopyridine (0.234 g, 1.914 mmol), and 1 (5.69 g, 21.5 mmol) was added 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide (4.128 g, 26.60 mmol). The mixture was stirred at room temperature under nitrogen atmosphere for 15 h, evaporated to remove CH2Cl2, and extracted with ethyl acetate/H2O three times.

The collected organic layer was dried over MgSO4, filtered, and

evaporated. The resultant residue was then purified by column chromatography on silica gel (ethyl acetae:hexane = 1:6, v/v) to furnish a transparent liquid (3.5 g, 62%): 1H NMR (CDCl

3, 300

MHz)δ 0.03 (s, 12H, Si(CH3)2), 0.86 (s, 18H, Si−C(CH3)3), 3.42 (s,

2H, (OC)CH2(CO)), 3.53 (t, J = 5.19 Hz, 4H, OCH2), 3.62−

3.63 (m, 8H, OCH2), 3.69 (t, J = 4.8 Hz, 4H, OCH2), 3.74 (t, J = 5.5

Hz, 4H, OCH2), 4.27 (t, J = 4.2 Hz, 4H, ((OC)OCH2);13C NMR

(CDCl3, 75 MHz)δ −5.3 (4C, Si−(CH3)2), 18.3 (2C, (Si−C(Me)3),

25.9 (6C, (Si−C(CH3)3), 41.2 (1C, (OC)CH2(CO)), 62.7 (2C,

OCH2), 64.6 (2C, OCH2), 68.8 (2C, OCH2), 70.6 (2C, OCH2), 70.7

(2C, OCH2), 72.7 (2C, OCH2), 166.5 (2C, CO).

Synthesis of Bis(TBDMS-triethylene glycol)-malonate Full-erene (3). To an anhydrous toluene (270 mL) solution of C60(0.3 g,

0.416 mmol) was added sequentially 2 (0.25 g, 0.419 mmol), I2(0.102

g, 0.402 mmol), and 1,8-diazabicyclo[5.4.0]undec-7-ene (0.159 g, 1.04 mmol). The reaction mixture was stirred for 20 h and then quenched with sodium thiosulfate aqueous solution. The organic layer was collected, evaporated, and purified by column chromatography on silica gel (toluene:methanol)ato give a crude product, which was then

reprecipitated from toluene/methanol to afford a brown solid (0.24 g, 44%):1H NMR (CDCl

3, 300 MHz,)δ 0.06 (s, 12H, Si(CH3)2), 0.89

(s, 18H, Si−C(CH3)3), 3.55 (t, J = 5.4 Hz, 4H, OCH2), 3.63−3.69 (m,

8H), 3.76 (t, J = 5.4 Hz, 4H, OCH2), 3.88 (t, J = 4.5 Hz, 4H, OCH2),

4.64 (t, J = 5.1 Hz, 4H, (OC)OCH2);13C NMR (CDCl3, 75 MHz)

δ −5.2 (4C, Si(CH3)2), 18.4 (2C, Si−C(Me)3), 25.8 (6C, Si−

C(CH3)3), 62.67, 66.2, 68.8, 70.7, 71.4, 72.7, 139.1, 140.9, 141.8,

142.2, 142.9, 143.0, 143.1, 143.9, 144.6, 144.7, 144.9, 145.2, 145.3, 163.5 (2C, CO). aInitially, only toluene was used as the eluent to remove pristine C60. Afterward, the eluent was changed to

toluene:methanol = 98:2, v/v for collecting crude product.

Synthesis of Bis(triethylene glycol) Malonate C60 (4). To a

THF (10 mL) solution of 3 (0.1 g, 0.076 mmol) was slowly added HCl (2 N, 1 mL). The reaction mixture was stirred vigorously at room temperature under nitrogen atmosphere for 30 min. An amount of 50 mL of CH2Cl2 was added, and the mixture was then washed by

saturated NaHCO3(aq)and H2O several times. The organic layer was

collected, dried over MgSO4, evaporated, and purified by column

chromatography on silica gel (CH2Cl2:methanol = 30:1, v/v). The

collected residue was then reprecipitated from CH2Cl2/hexane to

furnish a brown solid (60 mg, 72%):1H NMR (CDCl

3, 300 MHz)δ

3.02 (s, 2H, OH), 3.60−3.63 (m, 4H, OCH2), 3.67−3.70 (m, 4H,

OCH2), 3.72−3.75 (m, 8H, OCH2), 3.91 (t, J = 4.8 Hz, 4H, OCH2),

4.67 (t, J = 4.8 Hz, 4H, OC−OCH2);13C NMR(CDCl3, 75 MHz)δ

61.7, 66.1, 68.7, 70.4, 70.7, 72.7, 139.1, 140.9, 141.8, 142.2, 142.9, 143.0, 143.1, 143.9, 144.6, 144.7, 144.9, 145.1, 145.2, 145.3, 163.5 (2C, CO); MS (FAB, C75H26O10+•) calcd, 1086.1526; found, 1086.1520

Synthesis of Bis(triethylene glycol phthalic acid)-malonate C60(5). A mixture of 4 (0.05 g, 0.046 mmol), phthalic anhydride

(0.136 g, 0.92 mmol), and benzene (30 mL) was heated to the refluxing temperature, and 2.5 mL of pyridine was then added. The refluxing was continued for 20 h. The reaction mixture was evaporated and purified by column chromatography on silica gel (CH2Cl2:methanol = 30:1, v/v). The collected residue was then

reprecipitated from CH2Cl2/methanol to furnish a brown solid (43

mg, 67%):1H NMR (CDCl 3, 300 MHz)δ 3.68−3.70 (m, 4H, OCH2), 3.76 (t, J = 4.2 Hz, 4H, OCH2), 3.82−3.83 (m, 4H, OCH2), 4.02 (t, J = 3.9 Hz, 4H, OCH2), 4.44−4.46 (m, 4H, (OC)OCH2), 4.72 (t, J = 4.5 Hz, 4H, (OC)OCH2), 7.52−7.55 (m, 4H), 7.74−7.76 (m, 4H); 13C NMR (CDCl 3, 75 MHz)δ 64.7 (2C, OCH2), 65.7 (2C, OCH2),

68.8 (2C, OCH2), 68.9 (2C, OCH2), 69.7 (2C, OCH2), 70.9 (2C,

OCH2), 71.3, 128.9, 129.3, 130.9, 131.3, 131.5, 132.8, 138.9, 140.9,

141.8, 142.2, 142.9, 143.0, 143.8, 144.5, 144.6, 144.9, 145.1, 145.2, 145.2, 163.4 (2C, CO), 167.6 (2C, CO), 169.8 (2C, CO). MS (HR-FAB, C91H34O16+•) calcd, 1382.1847; found, 1382.1859.

Device Fabrication. An indium tin oxide (ITO)-coated glass substrate was ultrasonically washed by detergent, deionic water, acetone, and isopropanol sequentially for 15 min each and then cleaned by UV-ozone for another 15 min. PEDOT:PSS (Baytron PVP AI-4083) wasfiltered and spin-coated on a cleaned ITO-coated glass to produce a ca. 35 nm thick interlayer, which was then baked at 150 °C for 1 h. For active-layer fabrication, P3HT was mixed with PC61BM

in 1:1 weight ratio, and PCDCTBT-C8 was mixed with PC71BM in

1:3 weight ratio, respectively, in o-dichlorobenzene. The weight percent of P3HT:PC61BM in o-dichlorobenzene was 2 wt %, and that

of PCDTCBT:PC71BM was 1 wt %. The individual solutions were

heated and spin-coated on top of the PEDOT:PSS interlayer at 600 rpm. The resultantfilm was covered in a Petri dish to allow the solvent to slowly evaporate (solvent annealing) until thefilm was dried and then baked at 140°C for 10 min (thermal annealing). EGMC−OH or EGMC−COOH (2 mg) was then dissolved in mixed solvents (200 mg) and doped with an inorganic salt in some of the tested devices. The fullerene mixture was sonicated for 20 min,filtrated via a PVDF filter (45 μm), and spin-coated on top of the active layer at 3000 rpm for 60 s to give an 8 nm thick film. The top electrode was then prepared by sequential thermal evaporation of Ca (35 nm) and Al (100 nm) at reduced pressure below 10−6 Torr to furnish the BHJ solar cell devices. All devices contain an active area of 0.04 cm2, and

the photovoltaic parameters were measured at room temperature under air atmosphere with a Xenon lamp coupled to an AM 1.5G solar filter (SAN-EIXES-301S solar simulator). J−V characteristics were recorded in a Keitheley 2400 Source Measurement Unit.

■

RESULTS AND DISCUSSION

The synthetic procedure for the hydrophilic C

60derivatives is

described in Scheme 1. Triethylene glycol was treated with

tert-butyldimethylsilyl chloride (TBDMS-Cl) in the presence of

4-dimethylaminopyridine (DMAP) and triethylamine in

dichloro-methane to give tri(ethylene glycol) tert-butyldimethylsilyl

ether 1. Ester

fication of malonic acid with 1 by using

1-ethyl-3-(3-dimethylaminopropyl)carbodiimide and a catalytic amount

of DMAP yielded 2. Bingel reaction of C

60with 2 in the

presence of 1,8-diazabicyclo[5.4.0]undec-7-ene and I

2led to the

formation of bis(TBDMS-triethylene glycol)-malonate

full-erene 3. Desilylation of 3 with hydrochloric acid (2 M)

furnished bis(triethylene glycol) malonate C

60(EGMC

−OH,

4) which was reacted with phthalic anhydride to a

fford

bis(triethylene glycol phthalic acid)-malonate C

60(EGMC

−

COOH, 5). Their identities are fully characterized by NMR

spectroscopy and mass spectrometry.

The cyclic voltammograms of PC

61BM, EGMC

−OH, and

EGMC

−COOH are shown in Figure 1 and summarized in

Table 1. All voltammograms exhibit three well-de

fined,

single-electron reversible waves in the scanning range. The LUMO

energy levels of EGMC

−OH (−3.88 eV) and EGMC−COOH

(

−3.91 eV) are both lower than that of PC

61BM (

−3.85 eV).

The presence of the n-type EMLs can provide an extra donor

−

acceptor interface with the p-type material in the active layer for

exciton dissociation. On the other hand, the intrinsically

deep-lying HOMO energy level of EGMC

−OH and EGMC−

COOH

e

ffectively imparts the hole-blocking ability toward

p-type material to reduce the charge recombination at the

interfaces. The absorption spectra of EGMC

−OH and

EGMC

−COOH are depicted in Figure 2. Both spectra are

similar to each other with three distinct bands of ca. 258, 326,

and 426 nm in the CHCl

3solution.

The strategy of using hydrophilic EGMC

−OH and EGMC−

COOH

to construct the EML was then examined in

conventional solar cells. The devices are fabricated on the

basis of ITO/PEDOT:PSS/P3HT:PC

61BM/EML/Ca/Al

con-figuration. The current density−voltage characteristics of the

EGMC

−OH-based devices are illustrated in Figure 3, and their

device parameters are summarized in Table 2. For comparison,

the device without the EML was fabricated under otherwise

identical conditions and yielded an open-circuit voltage (V

oc) of

0.6 V, a short-circuit current (J

sc) of 9.02 mA cm

−2, a

fill factor

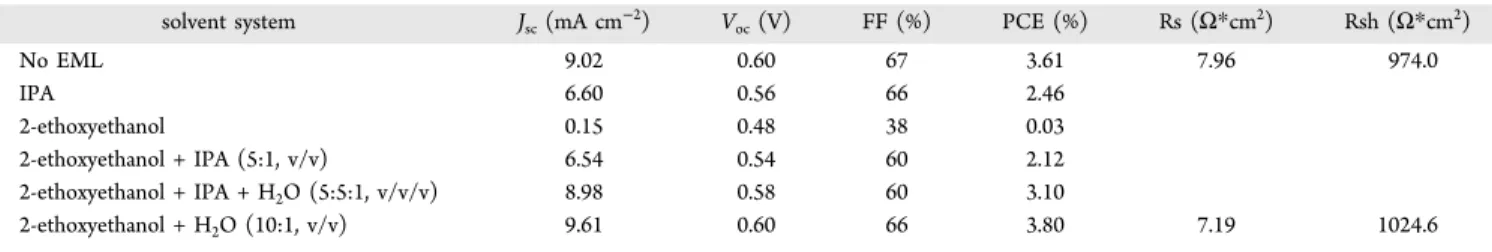

(FF) of 67%, and a PCE of 3.61%. The choice of polar solvents

for processing of the hydrophilic C

60plays an important role in

determining the

film-forming properties and the device

characteristics, as shown in Table 2. Employing a less polar

2-ethoxyethanolfurnished a low PCE of 0.02%, while the device

using isopropanol (IPA) as the solvent to deposit the EGMC

−

OH

layer gave a PCE of 2.41%. Both 2-ethoxyethanoland

isopropanol have a certain ability to dissolve PC

61BM in the

underlying active layer during the spin-coating of EGMC

−OH,

thus resulting in erosion and mixing of the active layer. The

PCE was optimized to 3.71% when 2-ethoxylethanol/H

2O

(10:1 v/v) was used as the processing cosolvent. The increased

polarity as a result of H

2O strengthens the orthogonal solvent

Figure 1. Cyclic voltammograms of PC61BM (black), EGMC−OH

(red), and EGMC−COOH (blue).

Table 1. Redox Potential and LUMO Energy Levels for

PC

61BM, EGMC−OH, and EGMC−COOH

compound E1pca(V) E1pab(V) E1redc(V) LUMOd(eV) EGMC−COOH −0.886 −0.736 −0.811 −3.91 EGMC−OH −0.910 −0.780 −0.845 −3.88 PC61BM −0.987 −0.752 −0.870 −3.85 aFrom the maximum of reduction potential.bFrom the maximum of oxidation potential.cFrom the equation Ered= 0.5(Epc+ Epa).dFrom

the equation LUMO =−(4.72 + Ered,onset).

Figure 2. Absorption spectra of EGMC−OH (red) and EGMC− COOH(blue).

Figure 3. Current density−voltage characteristics of ITO/PE-DOT:PSS/P3HT:PC61BM/EGMC−OH/Ca/Al devices under

effect, thus forming the EML layer without altering the

underlying active layer. Therefore, the formation of an

EGMC

−OH-based EML between the electrodes and the active

layers enhanced the electron-transporting characteristics at the

interfaces. A similar observation was found for the case of

EGMC

−COOH. The best efficiency of 3.80% was achieved

when 2-ethoxylethanol/H

2O (10:1 v/v) was used as the

cosolvent, indicating again the importance of utilizing highly

polar solvents (Figure 4, Table 3). The devices with EGMC

−

COOH

showed higher PCEs than those with EGMC

−OH.

These results may be presumably associated with the carboxylic

acid functionality on EGMC−COOH. The two carboxylic

groups might interact with the metal electrode and decrease the

ohmic contact between the EML and the electrode, thus

lowering the energy barrier for electron transporting from the

EML to the electrode.

16Furthermore, as can be concluded

from Table 2 and Table 3, after the installation of the EML, the

improvement of PCE mainly comes from the increase of J

sc,

while the V

ocand FF values remained generally unchanged. The

enhancement of J

scis in resonance with the diminution of the

device series resistance (Rs), indicating that the presence of the

EML can improve the device conductivity.

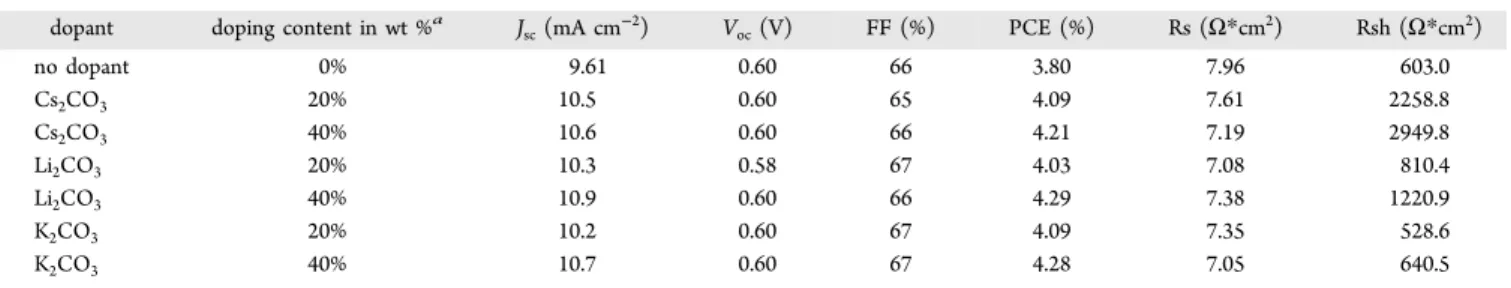

In an attempt to further optimize the electron-transporting

properties of the EML, n-dopant alkali carbonates were added

into the EGMC−OH and EGMC−COOH hosts.

15a−d,g,hAgain, a 2-ethoxylethanol/H

2O (10:1, v/v) cosolvent system

was used as the processing solvent for the following tests. As

demonstrated in Table 4 and Figure 3, the device performance

increased slightly upon the addition of Cs

2CO

3in EGMC

−

OH-based EMLs. A PCE of 3.80% was achieved when 40 wt %

Cs

2CO

3was doped. The presence of Cs

2CO

3can strengthen

the electron-transporting ability of the EML by increasing the

electron conductivity, thus resulting in the enhancement of J

scand PCE. The doping e

ffect is much more pronounced in the

case of EGMC

−COOH. An improved PCE of 4.21% was

obtained as the doping content was increased to 40 wt %

(Figure 5, Table 5). Encouraged by these results, we further

evaluated di

fferent carbonates, i.e., Li

2CO

3and K

2CO

3, which

were incorporated in the EGMC

−COOH-based EMLs as the

n-dopants. As summarized in Figure 5 and Table 5, 40 wt %

Li

2CO

3is capable of increasing the J

scfrom 9.61 mA cm

−2(without dopant) to 10.9 mA cm

−2and the PCE from 3.80%

(without dopant) to 4.29%. Similar results can also be found for

K

2CO

3(Figure 5, Table 5). The signi

ficant improvement of

PCE mainly comes from the increase of J

sc, while the V

ocand

FF values remained generally unchanged. These results suggest

again that alkali carbonates may enhance the conductivity of the

EML, which is supported by comparing the conductivity of

EGMC−COOH with and without doping of Cs

2CO

3(see

Figure S3 in the Supporting Information). Notably, this e

ffect is

more prominent in EGMC

−COOH than EGMC−OH. The

carboxylic acid groups of EGMC

−COOH may interact with

the carbonate bases from the ionic EGMC

−carboxylate salt

which is expected to have strong a

ffinity with the metal

Table 2. Photovoltaic Performances of the Devices Using EGMC

−OH as the EML

solvent system Jsc(mA cm−2) Voc(V) FF (%) PCE (%) Rs (Ω*cm2) Rsh (Ω*cm2)

no EML 9.02 0.60 67 3.61 10.00 603.0 IPA 6.52 0.56 66 2.41 2-ethoxyethanol 0.14 0.36 38 0.02 2-ethoxyethanol + IPA (5:1, v/v) 6.48 0.54 59 2.01 2-ethoxyethanol + IPA + H2O (5:5:1, v/v/v) 9.22 0.56 59 3.06 2-ethoxyethanol + H2O (10:1, v/v) 9.43 0.60 66 3.71 8.23 862.9

Figure 4. Current density−voltage characteristics of ITO/PE-DOT:PSS/P3HT:PC61BM/EGMC−COOH/Ca/Al devices under

illumination of AM1.5G at 100 mW cm−2.

Table 3. Photovoltaic Performances of the Devices Incorporating EGMC

−COOH as the EML

solvent system Jsc(mA cm−2) Voc(V) FF (%) PCE (%) Rs (Ω*cm2) Rsh (Ω*cm2)

No EML 9.02 0.60 67 3.61 7.96 974.0 IPA 6.60 0.56 66 2.46 2-ethoxyethanol 0.15 0.48 38 0.03 2-ethoxyethanol + IPA (5:1, v/v) 6.54 0.54 60 2.12 2-ethoxyethanol + IPA + H2O (5:5:1, v/v/v) 8.98 0.58 60 3.10 2-ethoxyethanol + H2O (10:1, v/v) 9.61 0.60 66 3.80 7.19 1024.6

Table 4. Photovoltaic Performances of the Devices

Incorporating EGMC

−OH Doped with Cs

2CO

3dopant doping content in wt %a Jsc (mA cm−2) Voc (V) FF (%) PCE (%) no dopant 0% 9.43 0.60 66 3.71 Cs2CO3 20% 9.64 0.60 65 3.74 Cs2CO3 40% 9.71 0.60 65 3.80 aWt % is the weight percentage of Cs

electrode. The ohmic contact between the EML and the

electrode is therefore reduced, leading to the enhancement of

J

scand PCE.

16To assess the applicability of the hydrophilic C

60materials

doped with alkali carbonates as an EML, a low band polymer

PCDCTBT

−C8 (Scheme 1) blended with PC

71BM was then

used as the active layer in a conventional device.

17The

reference device without the EML gave a V

ocof 0.72 V, a J

scof

8.72 mA cm

−2, a FF of 57%, and a PCE of 3.63% (Table 6).

The PCDCTBT

−C8:PC

71BM-based device using EGMC

−

COOH

as the EML doped with 40 wt % of Li

2CO

3delivered a

V

ocof 0.72 V, a J

scof 11.1 mA cm

−2, a FF of 56%, and a PCE of

4.51%, which represents a 24% enhancement. Analogous to the

P3HT:PC

61BM system, the improvement of PCE mainly

results from the increase of J

sc. This example demonstrates

the general applicability of using alcohol-/water-soluble C

60materials for improving the e

fficiency of conventional solar

cells.

■

CONCLUSIONS

We have rationally designed and synthesized two new C

60-based n-type materials, EGMC

−OH and EGMC−COOH,

functionalized with hydrophilic triethylene glycol groups. With

the assistance of the TEG-based surfactant, EGMC

−OH and

EGMC−COOH can be dissolved in highly polar solvents to

implement orthogonal solvent strategy, forming an electron

modi

fication layer without eroding the underlying active layer.

We found that 2-ethoxylethanol/H

2O (10:1, v/v) with higher

polarity is the best cosolvent to deposit the EGMC

−OH and

EGMC

−COOH EMLs. Multilayer conventional solar cells

(ITO/PEDOT:PSS/P3HT:PC

61BM/EML/Ca/Al) with

inser-tion of the C

60-modi

fier between the active layer and electrode

have been successfully realized by a cost-e

ffective solution

processing technique. Compared to the pristine device with a

power conversion e

fficiency (PCE) of 3.61%, the device

modi

fied by the EGMC−OH and EGMC−COOH EMLs

improved the PCEs to 3.71% and 3.8%, respectively. Moreover,

the electron-transporting properties of EGMC

−OH and

EGMC

−COOH can be further enhanced by the incorporation

of alkali carbonates as the n-dopants. Regardless of the

counterions, Cs

2CO

3, Li

2CO

3, as well as K

2CO

3carbonates

are all e

ffective to obtain higher efficiency. The device using

EGMC

−COOH doped with 40 wt % Li

2CO

3achieved a

highest PCE of 4.29%. The superior performance of EGMC

−

COOH

to EGMC

−OH might be associated to the existence of

the carboxylic functionality. Most importantly, the alcohol-/

water-soluble EGMC

−COOH can be applicable and effective

to other conventional devices. With the incorporation of the

EGMC

−COOH EML doped with 40 wt % Li

2CO

3, the

PCDCTBT-C8:PC

71BM-based device exhibited a superior

PCE of 4.51%, which outperformed the corresponding

nonmodi

fied device with a PCE of 3.63%.

■

ASSOCIATED CONTENT

*

S Supporting InformationThermal gravimetric analysis, cyclic voltammograms,

measure-ment of conductivity of EGMC

−COOH,

1H and

13C NMR

spectra, and mass spectrometry of the new materials. This

material is available free of charge via the Internet at http://

pubs.acs.org.

■

AUTHOR INFORMATION

Corresponding Author

*E-mail: yjcheng@mail.nctu.edu.tw and cshsu@mail.nctu.edu.

tw.

Notes

The authors declare no competing

financial interest.

■

ACKNOWLEDGMENTS

We thank the National Science Council and the

“ATU

Program

” of the Ministry of Education and the Center for

Interdisciplinary Science (CIS) of the National Chiao Tung

University Taiwan for

financial support.

Figure 5. Current density−voltage characteristics of ITO/PE-DOT:PSS/P3HT:PC61BM/EGMC−COOH/Ca/Al devices doped

with alkali carbonates.

Table 5. Photovoltaic Performances of the Devices Incorporating EGMC

−COOH Doped with Alkali Carbonates

dopant doping content in wt %a J

sc(mA cm−2) Voc(V) FF (%) PCE (%) Rs (Ω*cm2) Rsh (Ω*cm2) no dopant 0% 9.61 0.60 66 3.80 7.96 603.0 Cs2CO3 20% 10.5 0.60 65 4.09 7.61 2258.8 Cs2CO3 40% 10.6 0.60 66 4.21 7.19 2949.8 Li2CO3 20% 10.3 0.58 67 4.03 7.08 810.4 Li2CO3 40% 10.9 0.60 66 4.29 7.38 1220.9 K2CO3 20% 10.2 0.60 67 4.09 7.35 528.6 K2CO3 40% 10.7 0.60 67 4.28 7.05 640.5 aWt % is the weight percentage of alkali carbonates relative to EGMC−COOH.

Table 6. Photovoltaic Performances of the PCDCTBT

−

C8:PC

71BM-Based Devices Using EGMC

−COOH Doped

with 40 wt % Li

2CO

3as the EML

device Jsc(mA cm−2) Voc(V) FF (%) PCE (%) without EML 8.72 0.72 57 3.63 with EML 11.10 0.72 56 4.51

■

REFERENCES

(1) (a) Yu, G.; Gao, J.; Hummelen, J. C.; Wudl, F.; Heeger, A. J. Science 1995, 270, 1789−1791. (b) Günes, S.; Neugebauer, H.; Sariciftci, N. S. Chem. Rev. 2007, 107, 1324−1338. (c) Thompson, B. C.; Fréchet, J. M. J. Angew. Chem., Int. Ed. 2008, 47, 58−77. (d) Chen, J.; Cao, Y. Acc. Chem. Res. 2009, 42, 1709−1718. (e) Cheng, Y.-J.; Yang, S.-H.; Hsu, C.-S. Chem. Rev. 2009, 109, 5868−5923. (f) Zhou, H.; Yang, L.; You, W. Macromolecules 2012, 45, 607−632. (g) Li, Y.; Zou, Y. Adv. Mater. 2008, 20, 2952−2958. (h) Li, Y. Acc. Chem. Res. 2012, 45, 723−733.

(2) (a) Ma, W.; Yang, C.; Gong, X.; Lee, K.; Heeger, A. J. Adv. Funct. Mater. 2005, 15, 1617−1622. (b) Mayer, A. C.; Scully, S. R.; Hardin, B. E.; Rowell, M. W.; McGehee, M. D. Mater. Today 2007, 10, 28−33. (c) Li, G.; Shrotriya, V.; Huang, J.; Yao, Y.; Moriarty, T.; Emery, K.; Yang, Y. Nat. Mater. 2005, 4, 864−868. (d) Reyes-Reyes, M.; Kim, K.; Carroll, D. L. Appl. Phys. Lett. 2005, 87, 083506. (e) Woo, C. H.; Thompson, B. C.; Kim, B. J.; Toney, M. F.; Fréchet, J. M. J. J. Am. Chem. Soc. 2008, 130, 16324−16329.

(3) (a) Li, G.; Chu, C. W.; Shrotriya, V.; Huang, J.; Yang, Y. Appl. Phys. Lett. 2006, 88, 253503. (b) Liao, H.-H.; Chen, L.-M.; Xu, Z.; Li, G.; Yang, Y. Appl. Phys. Lett. 2008, 92, 173303. (c) Mor, G. K.; Shankar, K.; Paulose, M.; Varghese, O. K.; Grimes, C. A. Appl. Phys. Lett. 2007, 91, 152111. (d) Waldauf, C.; Morana, M.; Denk, P.; Schilinsky, P.; Coakley, K.; Choulis, S. A.; Brabec, C. J. Appl. Phys. Lett. 2006, 89, 233517. (e) White, M. S.; Olson, D. C.; Shaheen, S. E.; Kopidakis, N.; Ginley, D. S. Appl. Phys. Lett. 2006, 89, 143517. (f) Steim, R.; Choulis, S. A.; Schilinsky, P.; Brabec, C. J. Appl. Phys. Lett. 2008, 92, 093303. (g) Yang, T.; Cai, W.; Qin, D.; Wang, E.; Lan, L.; Gong, X.; Peng, J.; Cao, Y. J. Phys. Chem. C 2010, 114, 6849−6853. (4) (a) Cheng, Y.-J.; Hsieh, C.-H.; Li, P.-J.; Hsu, C.-S. Adv. Funct. Mater. 2011, 21, 1723−1732. (b) Kim, B. J.; Miyamoto, Y.; Ma, B.; Fréchet, J. M. J. Adv. Funct. Mater. 2009, 19, 2273−2281. (c) Gholamkhass, B.; Holdcroft, S. Chem. Mater. 2010, 22, 5371− 5376. (d) Drees, M.; Hoppe, H.; Winder, C.; Neugebauer, H.; Sariciftci, N. S.; Schwinger, W.; Schaeffler, F.; Topf, C.; Scharber, M. C.; Zhu, Z.; Gaudiana, R. J. Mater. Chem. 2005, 15, 5158−5163.

(5) (a) Li, C.-Z.; Yip, H.-L.; Jen, A. K.-Y. J. Mater. Chem. 2012, 22, 4161−4177. (b) Ma, H.; Yip, H.-L.; Huang, F.; Jen, A. K.-Y. Adv. Funct. Mater. 2010, 20, 1371−1388. (c) Yip, H.-L.; Jen, A. K.-Y. Energy Environ. Sci 2012, 5, 5994−6011. (d) Huang, F.; Jen, A. K.-Y. In Organic Electronics; CRC Press: Boca Raton, FL, 2009; pp 243−261.

(6) Hau, S. K.; Yip, H.-L.; Baek, N. S.; Zou, J.; O’Malley, K.; Jen, A. K. Y. Appl. Phys. Lett. 2008, 92, 253301.

(7) (a) Lee, K.; Kim, J. Y.; Park, S. H.; Kim, S. H.; Cho, S.; Heeger, A. J. Adv. Mater. 2007, 19, 2445−2449. (b) Gilot, J.; Wienk, M. M.; Janssen, R. A. J. Appl. Phys. Lett. 2007, 90, 143512. (c) Hayakawa, A.; Yoshikawa, O.; Fujieda, T.; Uehara, K.; Yoshikawa, S. Appl. Phys. Lett. 2007, 90, 163517.

(8) Brabec, C. J.; Shaheen, S. E.; Winder, C.; Sariciftci, N. S.; Denk, P. Appl. Phys. Lett. 2002, 80, 1288−1290.

(9) (a) Liao, H.-H.; Chen, L.-M.; Xu, Z.; Li, G.; Yang, Y. Appl. Phys. Lett. 2008, 92, 173303. (b) Chen, F.-C.; Wu, J.-L.; Yang, S. S.; Hsieh, K.-H.; Chen, W.-C. J. Appl. Phys. 2008, 103, 103721.

(10) (a) Zhang, F.; Ceder, M.; Inganäs, O. Adv. Mater. 2007, 19, 1835−1838. (b) Chen, F.-C.; Chien, S.-C. J. Mater. Chem. 2009, 19, 6865−6869.

(11) (a) Oh, S.-H.; Na, S.-I.; Jo, J.; Lim, B.; Vak, D.; Kim, D.-Y. Adv. Funct. Mater. 2010, 20, 1977−1983. (b) He, Z.; Zhang, C.; Xu, X.; Zhang, L.; Huang, L.; Chen, J.; Wu, H.; Cao, Y. Adv. Mater. 2011, 23, 3086−3089. (c) Luo, J.; Wu, H.; He, C.; Li, A.; Yang, W.; Cao, Y. Appl. Phys. Lett. 2009, 95, 043301. (d) Duarte, A.; Pu, K.-Y.; Liu, B.; Bazan, G. C. Chem. Mater. 2010, 23, 501−515. (e) He, C.; Zhong, C.; Wu, H.; Yang, R.; Yang, W.; Huang, F.; Bazan, G. C.; Cao, Y. J. Mater. Chem. 2010, 20, 2617−2622. (f) Seo, J. H.; Gutacker, A.; Sun, Y.; Wu, H.; Huang, F.; Cao, Y.; Scherf, U.; Heeger, A. J.; Bazan, G. C. J. Am. Chem. Soc. 2011, 133, 8416−8419. (g) He, Z.; Zhong, C.; Huang, X.; Wong, W.-Y.; Wu, H.; Chen, L.; Su, S.; Cao, Y. Adv. Mater. 2011, 23, 4636−4643. (h) He, Z.; Zhong, C.; Su, S.; Xu, M.; Wu, H.; Cao, Y. Nature Photon. 2012, 6, 591−595. (i) Duan, C.; Zhang, K.; Guan, X.;

Zhong, C.; Xie, H.; Huang, F.; Chen, J.; Peng, J.; Cao, Y. Chem. Sci. 2013, 4, 1298−1307. (j) Guan, X.; Zhang, K.; Huang, F.; Bazan, G. C.; Cao, Y. Adv. Funct. Mater. 2012, 22, 2846−2854.

(12) (a) Wei, Q.; Nishizawa, T.; Tajima, K.; Hashimoto, K. Adv. Mater. 2008, 20, 2211−2216. (b) Jung, J. W.; Jo, J. W.; Jo, W. H. Adv. Mater. 2011, 23, 1782−1787. (c) Hau, S. K.; Cheng, Y.-J.; Yip, H.-L.; Zhang, Y.; Ma, H.; Jen, A. K. Y. ACS Appl. Mater. Interfaces 2010, 2, 1892−1902. (d) Duan, C.; Zhong, C.; Liu, C.; Huang, F.; Cao, Y. Chem. Mater. 2012, 24, 1682−1689. (e) Chang, C.-Y.; Wu, C.-E.; Chen, S.-Y.; Cui, C.; Cheng, Y.-J.; Hsu, C.-S.; Wang, Y.-L.; Li, Y. Angew. Chem., Int. Ed. 2011, 50, 9386−9390. (f) Cheng, Y.-J.; Hsieh, C.-H.; He, Y.; Hsu, C.-S.; Li, Y. J. Am. Chem. Soc. 2010, 132, 17381− 17383. (g) Cheng, Y.-J.; Cao, F.-Y.; Lin, W.-C.; Chen, C.-H.; Hsieh, C.-H. Chem. Mater. 2011, 23, 1512−1518. (h) Hsieh, C.-H.; Cheng, Y.-J.; Li, P.-J.; Chen, C.-H.; Dubosc, M.; Liang, R.-M.; Hsu, C.-S. J. Am. Chem. Soc. 2010, 132, 4887−4893.

(13) (a) Cheng, Y.-J.; Liao, M.-H.; Shih, H.-M.; Shih, P.-I. Macromolecules 2011, 44, 5968−5976. (b) Huang, F.; Cheng, Y.-J.; Zhang, Y.; Liu, M. S.; Jen, A. K. Y. J. Mater. Chem. 2008, 18, 4495− 4509. (c) Cheng, Y.-J.; Liu, M. S.; Zhang, Y.; Niu, Y.; Huang, F.; Ka, J.-W.; Yip, H.-L.; Tian, Y.; Jen, A. K. Y. Chem. Mater. 2007, 20, 413−422. (d) Müller, C. D.; Falcou, A.; Reckefuss, N.; Rojahn, M.; Wiederhirn, V.; Rudati, P.; Frohne, H.; Nuyken, O.; Becker, H.; Meerholz, K. Nature 2003, 421, 829−833.

(14) (a) Ayzner, A. L.; Tassone, C. J.; Tolbert, S. H.; Schwartz, B. J. J. Phys. Chem. C 2009, 113, 20050−20060. (b) Hagemann, O.; Bjerring, M.; Nielsen, N. C.; Krebs, F. C. Sol. Energy Mater. Sol. Cells 2008, 92, 1327−1335. (c) Zakhidov, A. A.; Lee, J.-K.; Fong, H. H.; DeFranco, J. A.; Chatzichristidi, M.; Taylor, P. G.; Ober, C. K.; Malliaras, G. G. Adv. Mater. 2008, 20, 3481−3484. (d) Sax, S.; Rugen-Penkalla, N.; Neuhold, A.; Schuh, S.; Zojer, E.; List, E. J. W.; Müllen, K. Adv. Mater. 2010, 22, 2087−2091.

(15) (a) Barbot, A.; Di, B. C.; Lucas, B.; Ratier, B.; Aldissi, M. J. Mater. Sci. 2013, 48, 2785−2789. (b) Xu, Z.-Q.; Yang, J.-P.; Sun, F.-Z.; Lee, S.-T.; Li, Y.-Q.; Tang, J.-X. Org. Electron. 2012, 13, 697−704. (c) He, M.; Jung, J.; Qiu, F.; Lin, Z. J. Mater. Chem. 2012, 22, 24254− 24264. (d) Cai, Y.; Wei, H. X.; Li, J.; Bao, Q. Y.; Zhao, X.; Lee, S. T.; Li, Y. Q.; Tang, J. X. Appl. Phys. Lett. 2011, 98, 113304. (e) Huang, F.; Shih, P.-I.; Shu, C.-F.; Chi, Y.; Jen, A. K. Y. Adv. Mater. 2009, 21, 361− 365. (f) Huang, F.; Shih, P.-I.; Liu, M. S.; Shu, C.-F.; Jen, A. K. Y. Appl. Phys. Lett. 2008, 93, 243302. (g) Wu, C.-I.; Lin, C.-T.; Chen, Y.-H.; Chen, M.-H.; Lu, Y.-J.; Wu, C.-C. Appl. Phys. Lett. 2006, 88, 152104. (h) Chen, S.-Y.; Chu, T.-Y.; Chen, J.-F.; Su, C.-Y.; Chen, C. H. Appl. Phys. Lett. 2006, 89, 053518.

(16) (a) O’Malley, K. M.; Li, C.-Z.; Yip, H.-L.; Jen, A. K. Y. Adv. Energy Mater. 2012, 2, 82−86. (b) Li, C.-Z.; Chueh, C.-C.; Yip, H.-L.; O’Malley, K. M.; Chen, W.-C.; Jen, A. K. Y. J. Mater. Chem. 2012, 22, 8574−8578.

(17) Cheng, Y.-J.; Wu, J.-S.; Shih, P.-I.; Chang, C.-Y.; Jwo, P.-C.; Kao, W.-S.; Hsu, C.-S. Chem. Mater. 2011, 23, 2361−2369.